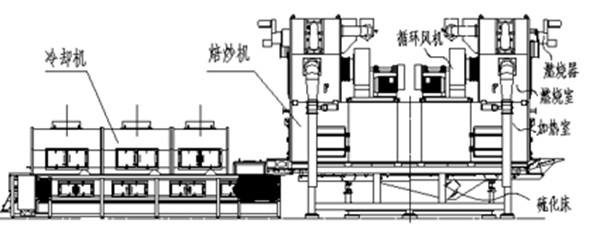

Grain Roasting Machine + CoolerGrain Roasting Machine:Use natural gas to heat the air, send it into the fluidized bed through a high-temperature fan, to contact the material evenly and fully, and roast it.Cooler:The roasted materials are fed into the air box through the stainless steel mesh belt, the upper layer is fed with cold air, and the lower layer extracts the air. The cold air is fully in contact with the material to achieve cooling.

Grain Roasting Machine:

Use natural gas to heat the air, send it into the fluidized bed through a high-temperature fan, to contact the material evenly and fully, and roast it.

Cooler:

The roasted materials are fed into the air box through the stainless steel mesh belt, the upper layer is fed with cold air, and the lower layer extracts the air. The cold air is fully in contact with the material to achieve cooling.

The material is conveyed and heated in a straight line, and there is no circulating heating state, so there will be no burning, coking caused fire or explosion problems.

Natural gas is used as fuel, clean and environmentally friendly, and high-temperature wind energy is recycled, with high utilization rate and resource saving.

Accurate temperature control, with a specially designed roasting circular air duct. The material is in direct contact with high-temperature air, and continuously tumbling and roasting to achieve even roasting. The material properties are uniform and stable with low scorched rate. The material moisture content and degree of gelatinization meet the process requirements, and the comprehensive energy efficiency is high.

The grain roasting machine is equipped with natural gas leakage detection, the combustion chamber, heating chamber, and flue are equipped with high temperature detection, and there are multiple sets of automatic steam fire extinguishing devices, which can realize high temperature warning and automatic fire extinguishing, and the equipment is safe and reliable.

The roasting process is automatic, and is controlled by touch screen, which can easily adjust the roasting parameters, and easy for the staff to operate.

The equipment has good heat preservation, and is equipped with a parameterized heat removal system, and the working environment is good.

There is a temperature sensor at the end of the cooler to realize automatic control of wind frequency. The material is cooled evenly, and the effect is good.

Technical parameters of grain roasting machine/model | Processing Capacity | Natural Gas Consumption (m3/h) | Gelatinization Rate (%) | Power (kW) |

BCJ-1500 | 1500 | 30~35 | 60%~65% | 65 |

BCJ-3000 | 3000 | 60~70 | 60%~65% | 120 |

BCJ-6000 | 6000 | 120~140 | 60%~65% | 230 |

Cooler technical parameters/model | Capacity (kg/h) | Feeding Temperature (℃) | Discharging Temperature (℃) | Conveying Method |

LQJ-1500 | 1500 | ≤145 | ≤38 | Stainless steel mesh belt |

LQJ-3000 | 3000 | ≤145 | ≤38 | Stainless steel mesh belt |

LQJ-6000 | 6000 | ≤145 | ≤38 | Stainless steel mesh belt |

| Model/Technical Parameters of Grain Roasting Machine | Processing Capacity | Natural Gas Consumption (m3/h) |

BCJ-150 | 1500 | 30~35 |

BCJ-300 | 3000 | 60~70 |

BCJ-6000 | 600 | 120~140 |

Gelatinization Rate (%) | Power (kW) |

| 60%~65% | 65 |

| 60%~65% | 120 |

| 60%~65% | 230 |

| Model/Technical Parameters of Cooler | Capacity (kg/h) | Feeding Temperature (℃) |

LQJ-1500 | 1500 | ≤145 |

LQJ-3000 | 3000 | ≤145 |

LQJ-6000 | 6000 | ≤145 |

Discharging Temperature (℃) | Conveying Method |

| ≤38 | Stainless steel mesh belt |

| ≤38 | Stainless steel mesh belt |

| ≤38 | Stainless steel mesh belt |