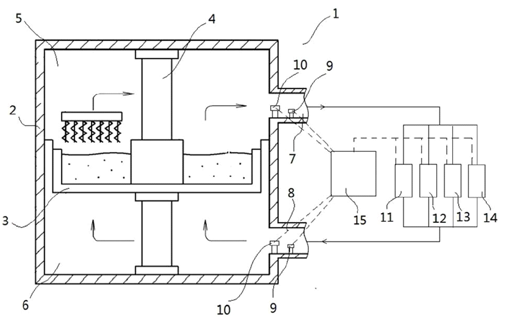

Disc Koji-Making System: It is a set of automatic cultivation system, which can realize automatic feeding, discharging, automatic turning, automatic temperature control, humidity control and automatic ventilation; it also will be dried and cooled after washing to ensure cleanness and sanitary; the equipment meets the production process requirements of brewing industry.

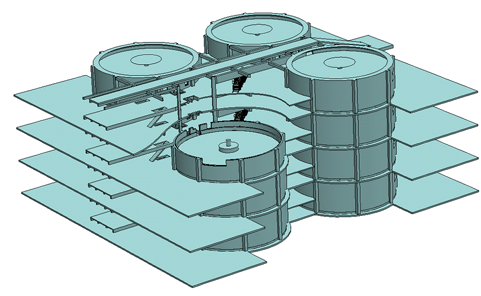

1. According to the discharging procedure, it can automatically descend in sections and discharge in layers.

2. Accurate positioning, scraper plate setting, and clean discharging.

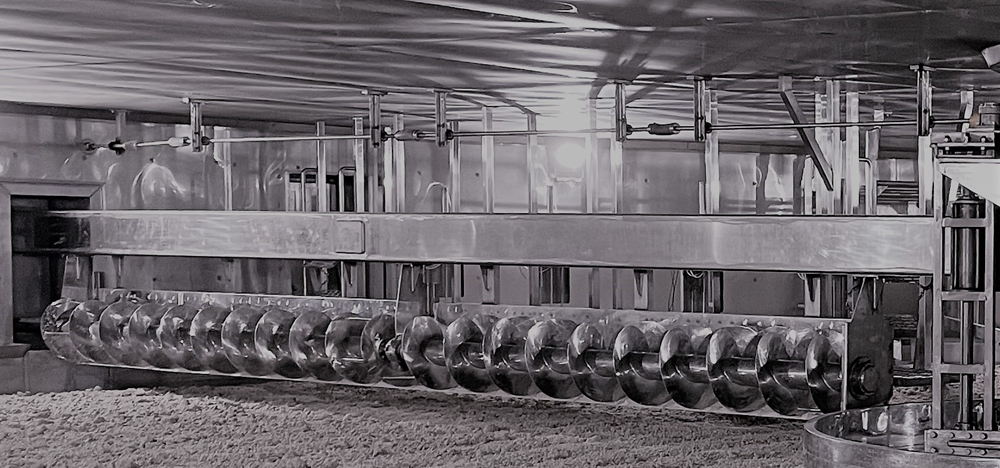

1.According to the geometric structure of the disc, a progressive speed decreasing transmission structure from the outer ring to the inner ring of the screw conveyor is designed.

2.The screw conveyor is a special structure, which ensures the efficiency and quality of koji-turning.

3.According to the program, it can automatically descend to turn the koji and locate accurately.

1. A set of rotating feeding belt, matched with multiple discs, performs the feeding process.

2. Under the action of the control program, the belt conveying speed, moving speed and the rotation speed of the disc are changed automatically to achieve smooth material spreading.

The system is highly automatic and has realized unmanned management: the feeding, koji-turning, discharging and the air volume, air pressure, temperature, humidity and other key factors in the process of koji-making are automatically controlled by the koji making program and will form a database.

High adaptability, and humanized operation can be realized: with parameterized visual window, the parameters of koji-making can be adjusted according to the process requirements of different customers to achieve the most suitable cultivation environment.

The disc koji-making machine adopts automatic belt spreading: through the establishment of a feeding mathematical model and an automatic feeding program, the even and smooth feeding is realized, and the problem of large temperature differences caused by uneven materials is avoided.

The team transforms the rich experience of process and management into equipment intelligent technology to realize unmanned production, intelligent fault diagnosis, maintenance and output, equipment remote maintenance, and big data collection.

The disc body is made with high precision: less material leakage, high degree of flatness of the disc surface and analysis platform, etc., and the koji-turning is thorough. there is basically no residual material on the disc surface after discharging,.

The YP type disc koji-making machine has a high degree of sealing, and the entire cultivation process can prevent external bacteria from entering and causing pollution effectively; manual operation outside the koji house has greatly improved the working environment.

Koji-making fan, disc rotation driving motor, feeding, loosening, and output motors are all controlled by frequency converters, which are energy-saving and operating automatically.

Disc Specifications | Koji-making Area (m2) | Disc Diameter (mm) | Koji-making Thickness (mm) | Koji-making Weight per set (T) | Machine Power (kW) |

| YP-10 | 75 | 10000 | ≤600 | ≤18 | 80 |

| YP-14 | 150 | 14000 | ≤600 | ≤30 | 160 |

| YP-16 | 200 | 16000 | ≤600 | ≤45 | 200 |

| YP-17 | 220 | 17000 | ≤600 | ≤50 | 240 |

YP-20 | 300 | 20000 | ≤600 | ≤70 | 270 |

Disc Specifications | Koji-making Area (m2) | Disc Diameter (mm) |

| YP-10 | 75 | 10000 |

| YP-14 | 150 | 14000 |

| YP-16 | 200 | 16000 |

| YP-17 | 220 | 17000 |

YP-20 | 300 | 20000 |

Koji-making Thickness (mm) | Koji-making Weight per set (T) | Machine Power (kW) |

| ≤600 | ≤18 | 80 |

| ≤600 | ≤30 | 160 |

| ≤600 | ≤45 | 200 |

| ≤600 | ≤50 | 240 |

| ≤600 | ≤70 | 270 |